Project name: PSMFC-mytilus-byssus-pilot

Funding source: Pacific States Marine Fisheries Commission

Species: mytilus galloprovincialis, mytilus trossulus

variable: OA, DO, seawater temperature, desiccation

1. Specimen collection

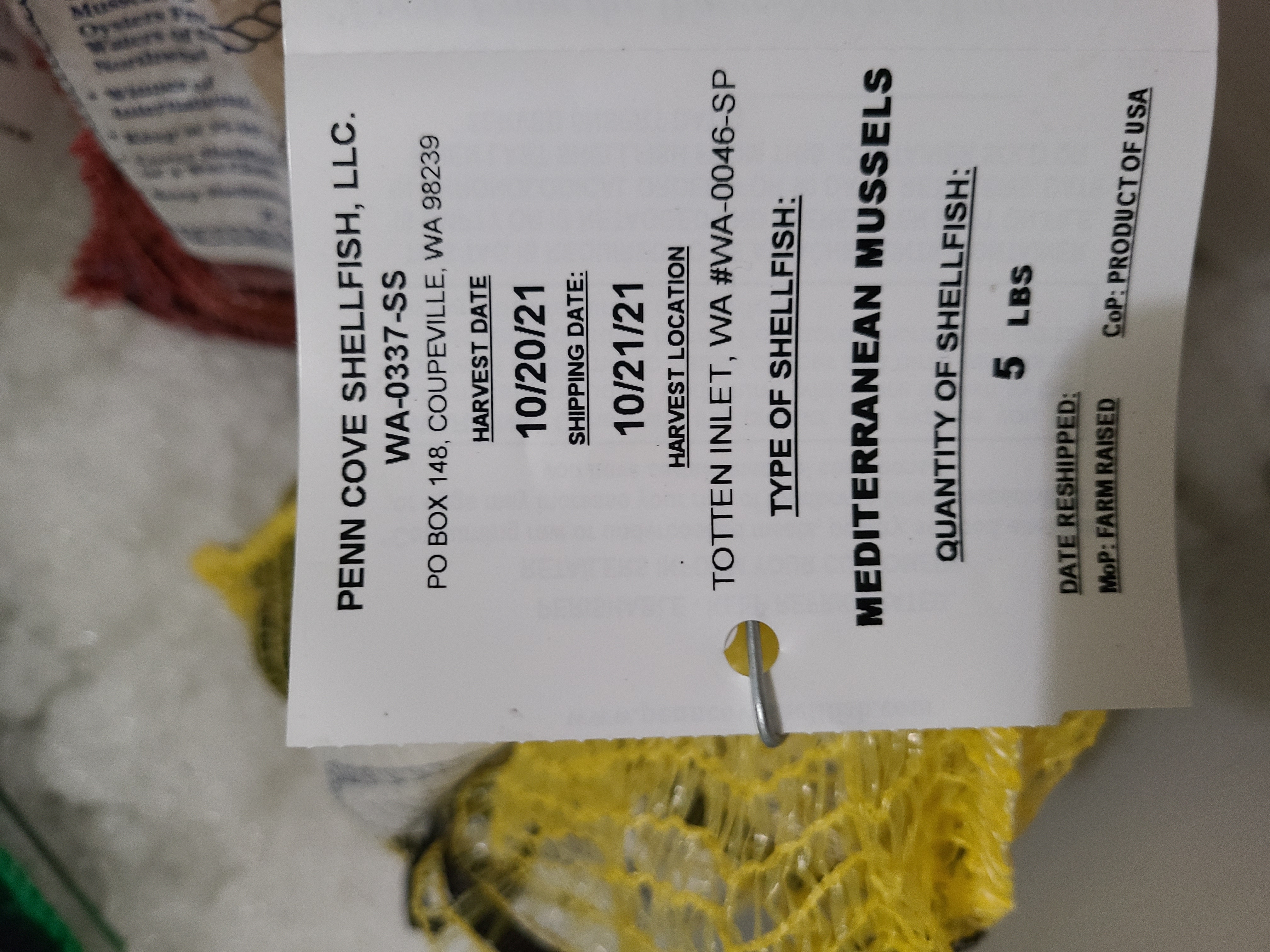

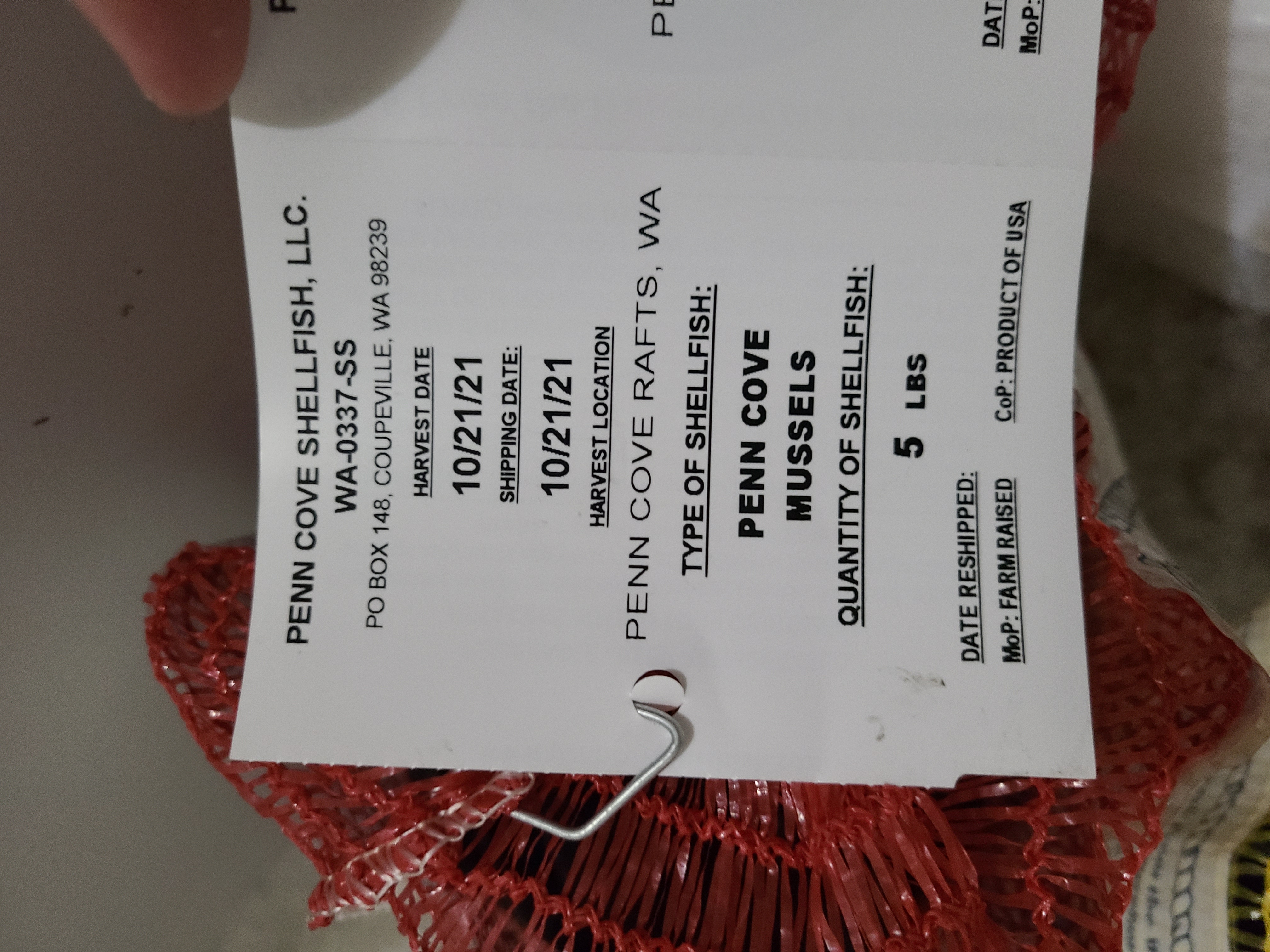

500 Mussels (Mytilus trossulus and M. galloprovincialis) were collected from Penn Cove Shellfish’s farm located on Whidbey Island, WA. Mussels were removed directly from aquaculture lines to prevent stress associated with harvesting/packaging. Here are a few pictures of the farm:

|

|

|

|

|

|

2. Thread production

2.1. Material selection and sourcing

Our goal was to have mussels produce threads on mica. Mica is a great surface due to its hydrophilicity and crystalline structure - resulting in a smooth and reproducible surface to detect differences in adhesion, absent of artifacts from surface topography or chemical heterogeneity. If unavailable, alternatives include cellulose acetate. Metals and hydrophobic surfaces should be avoided (unless part of the study design).

Sheets of mica can be purchased from various suppliers. The main challenge is getting enough sheets in the right size range / thickness. The keyword to search for is natural “muscovite” mica sheets/tile for craft or insulation purposes. Stuff like this won’t work - the mica is ground up, mixed with a thermo-resilient adhesive, and pressed into shapes. You can buy natural large slabs but they are often too thick, not uniformly shaped, and expensive. Inexpensive sheets like this would be great, but they are cut too small. The minimum size that I have used in the past were 2” x 2.3” x 0.1” (thickness).

Here are a few options I found:

- This etsy seller has tiles in 2”x3”, 3”x3”, and 3”x5” sizes, sold in packages of 10. You could buy across multiple sizes and cut so they are uniform. Rather expensive. Delivery by the end of month (maybe see if you can ship direct to France?)

- There looks to be a direct supplier listed on alibaba. Cheap pricing and will cut to size and provide bulk pricing. Worth reaching out and ordering a bunch for future projects.

2.2. Mussel platform construction

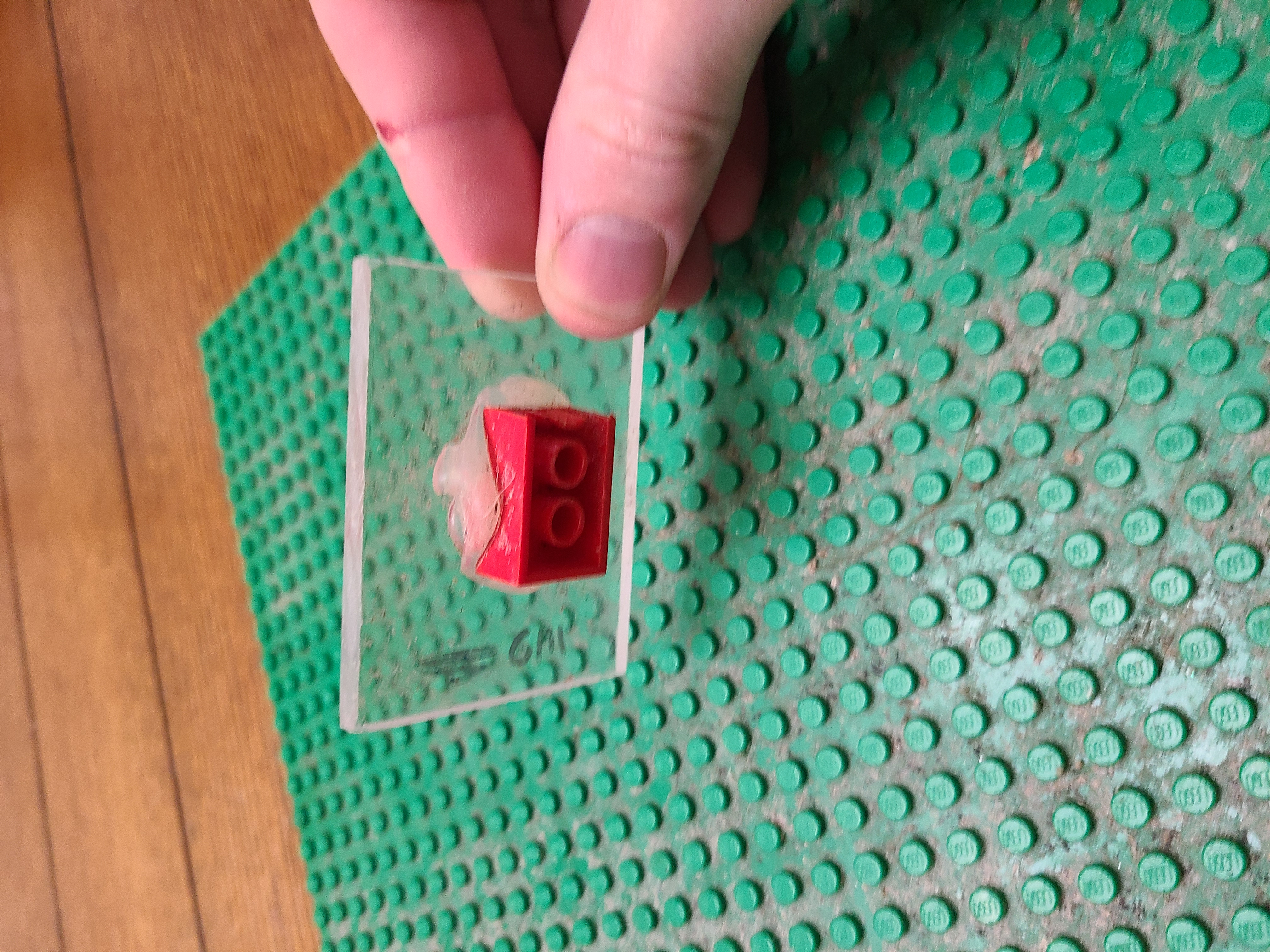

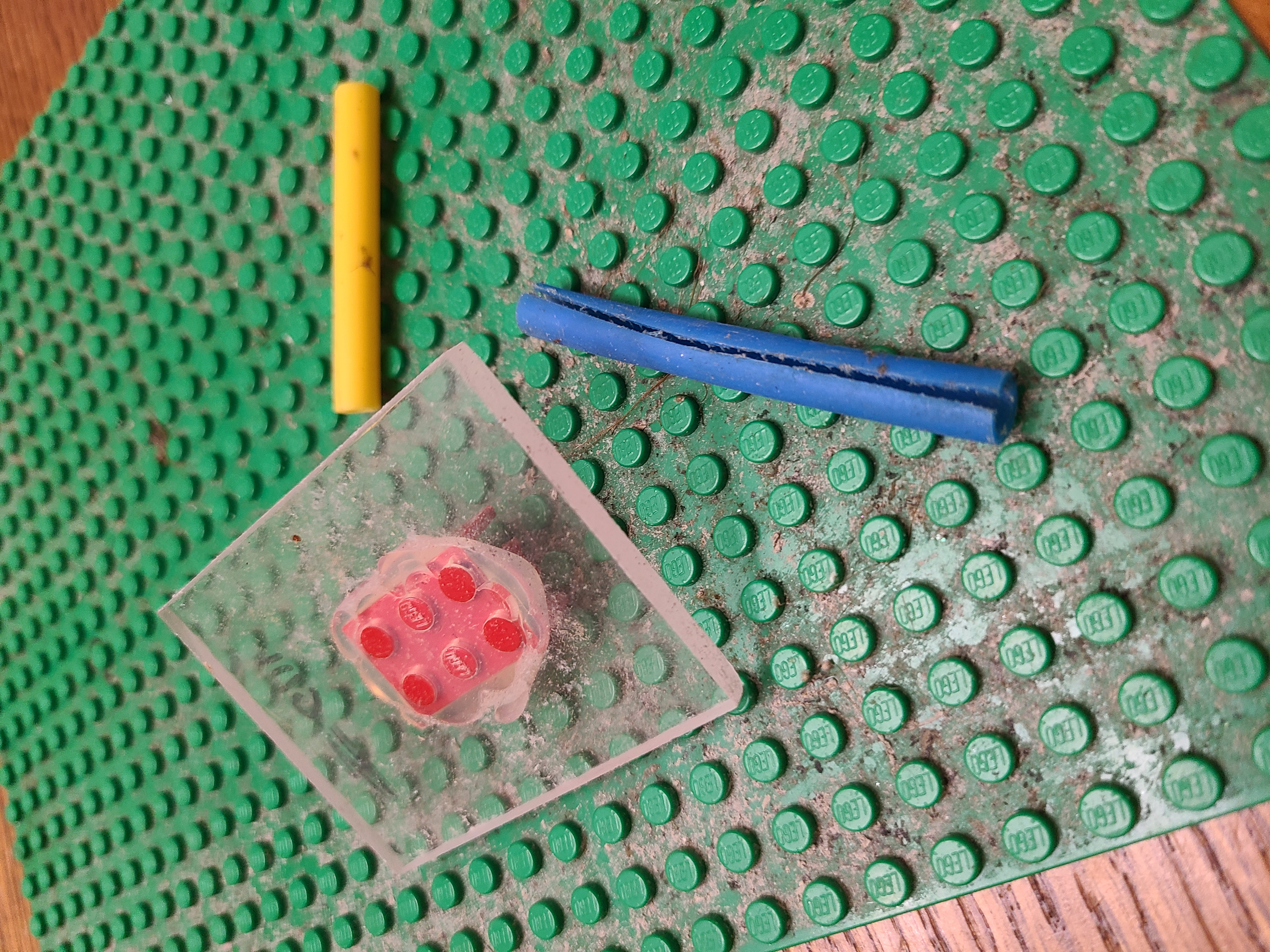

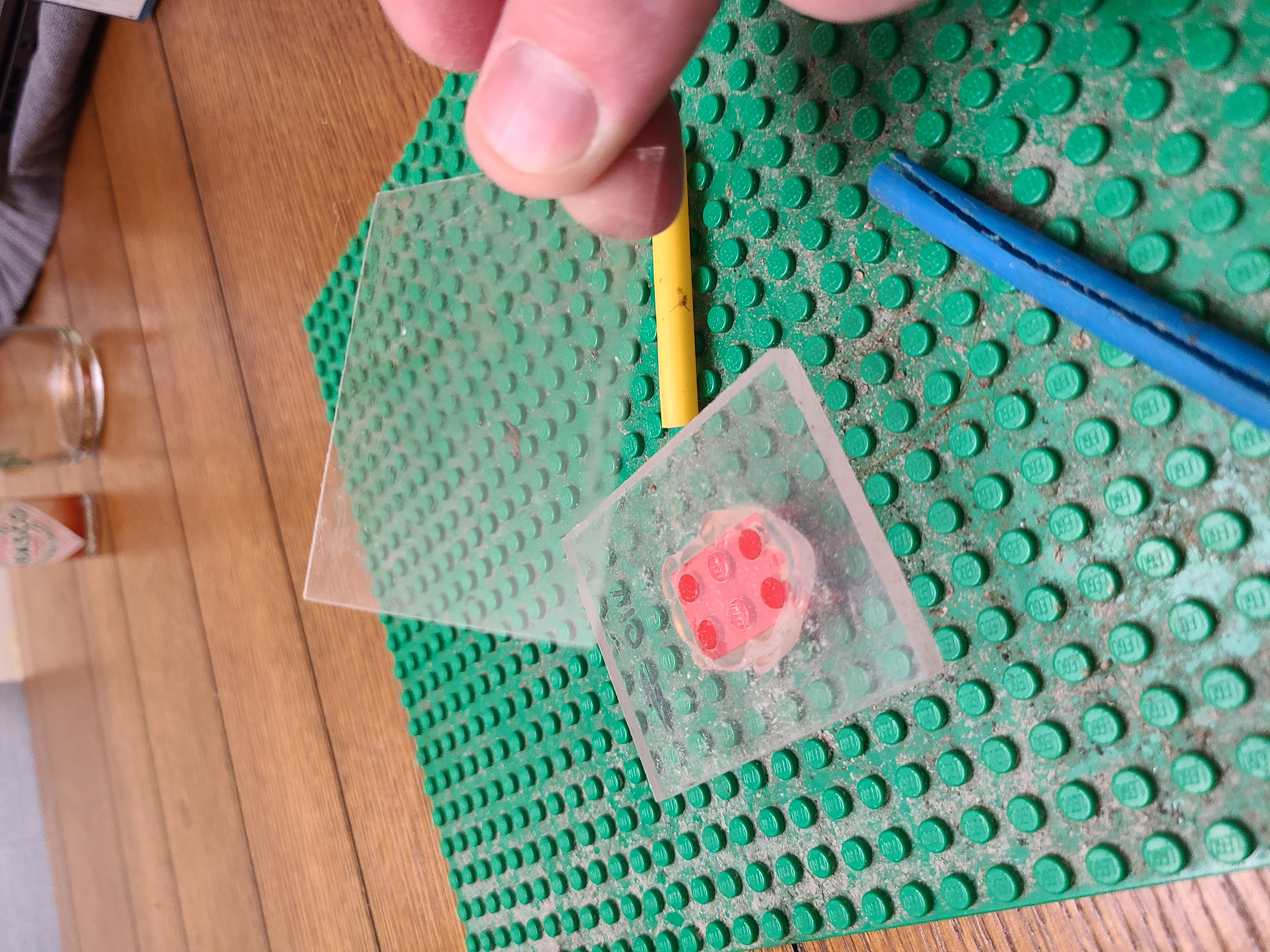

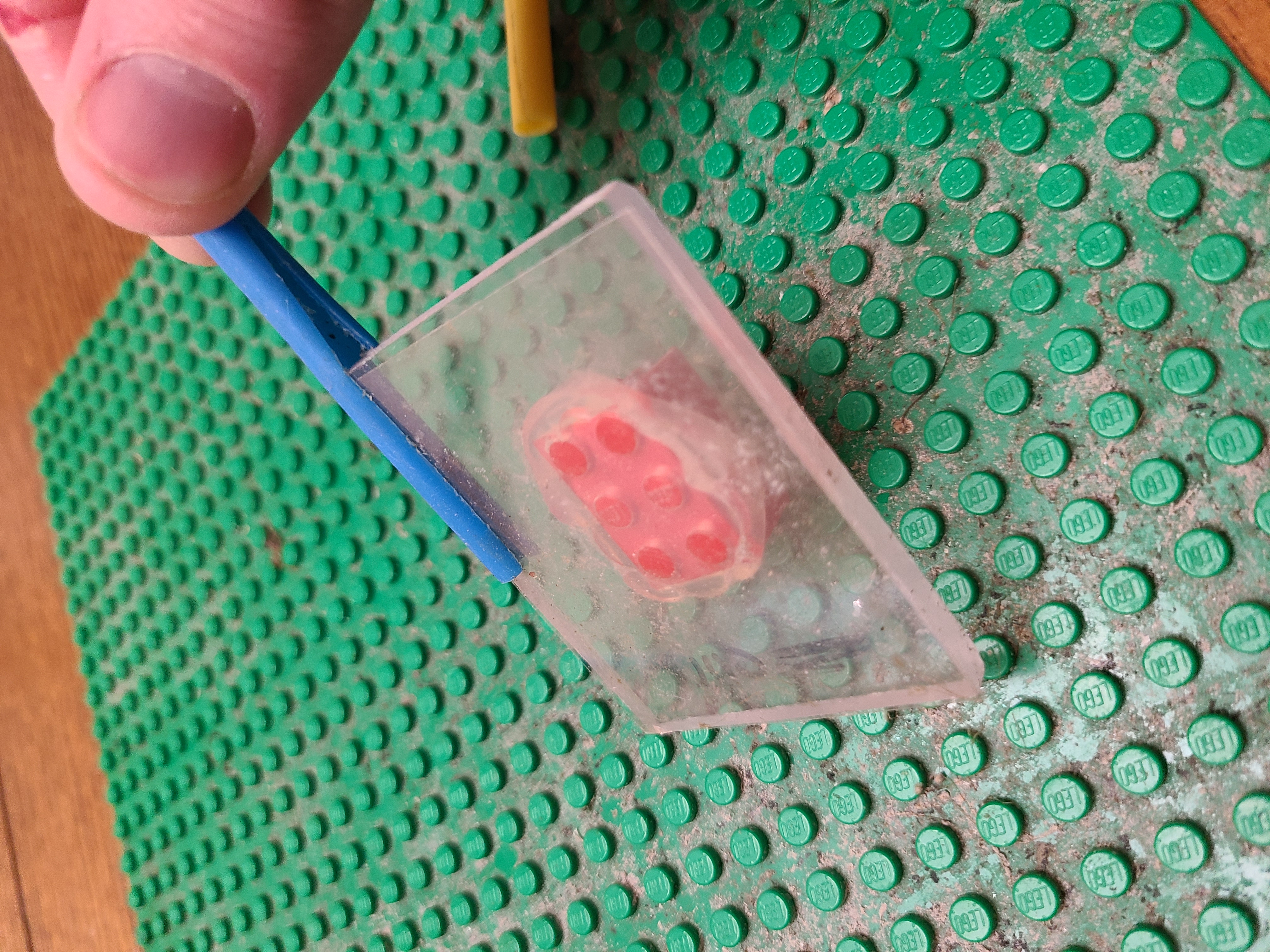

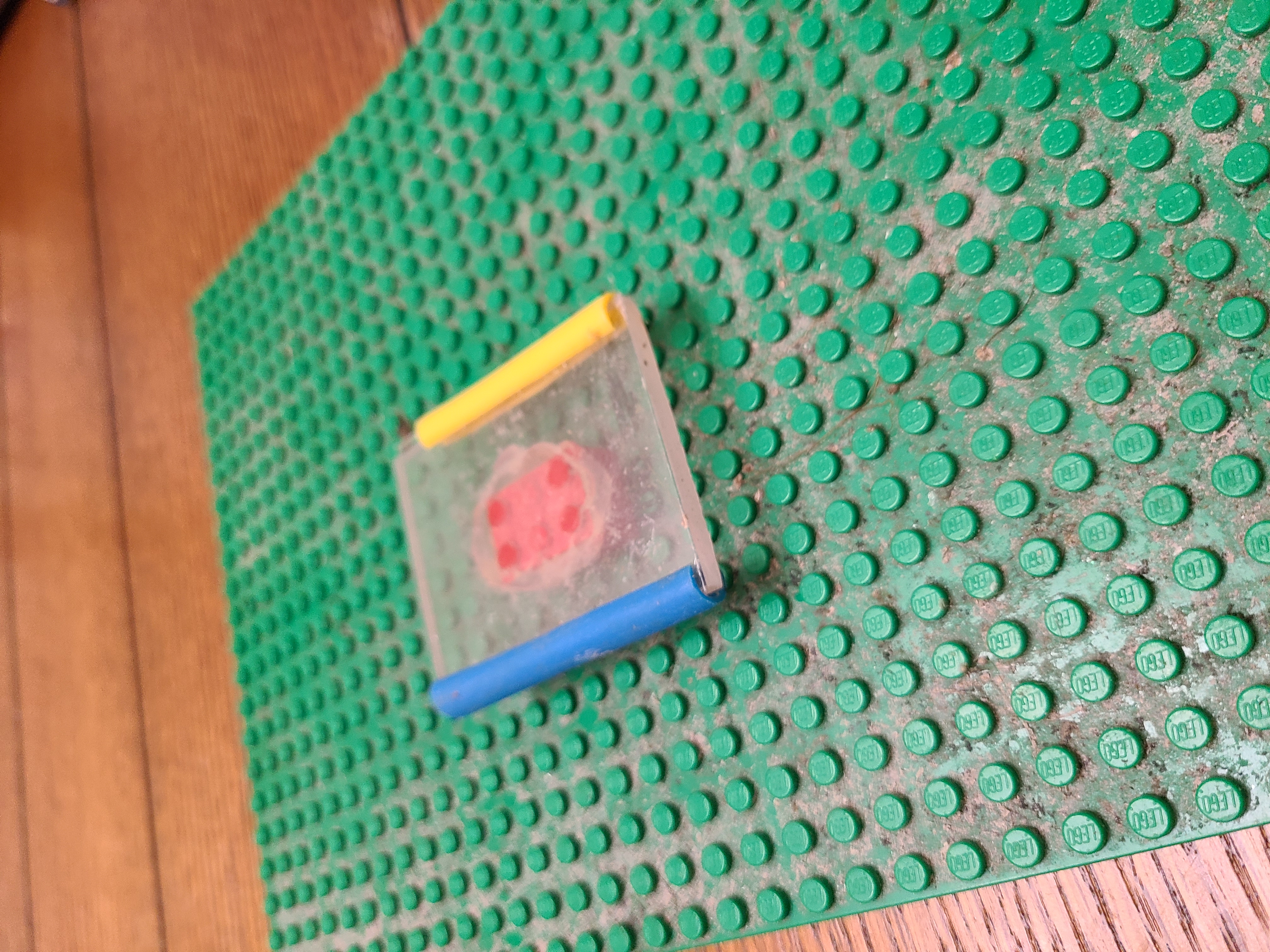

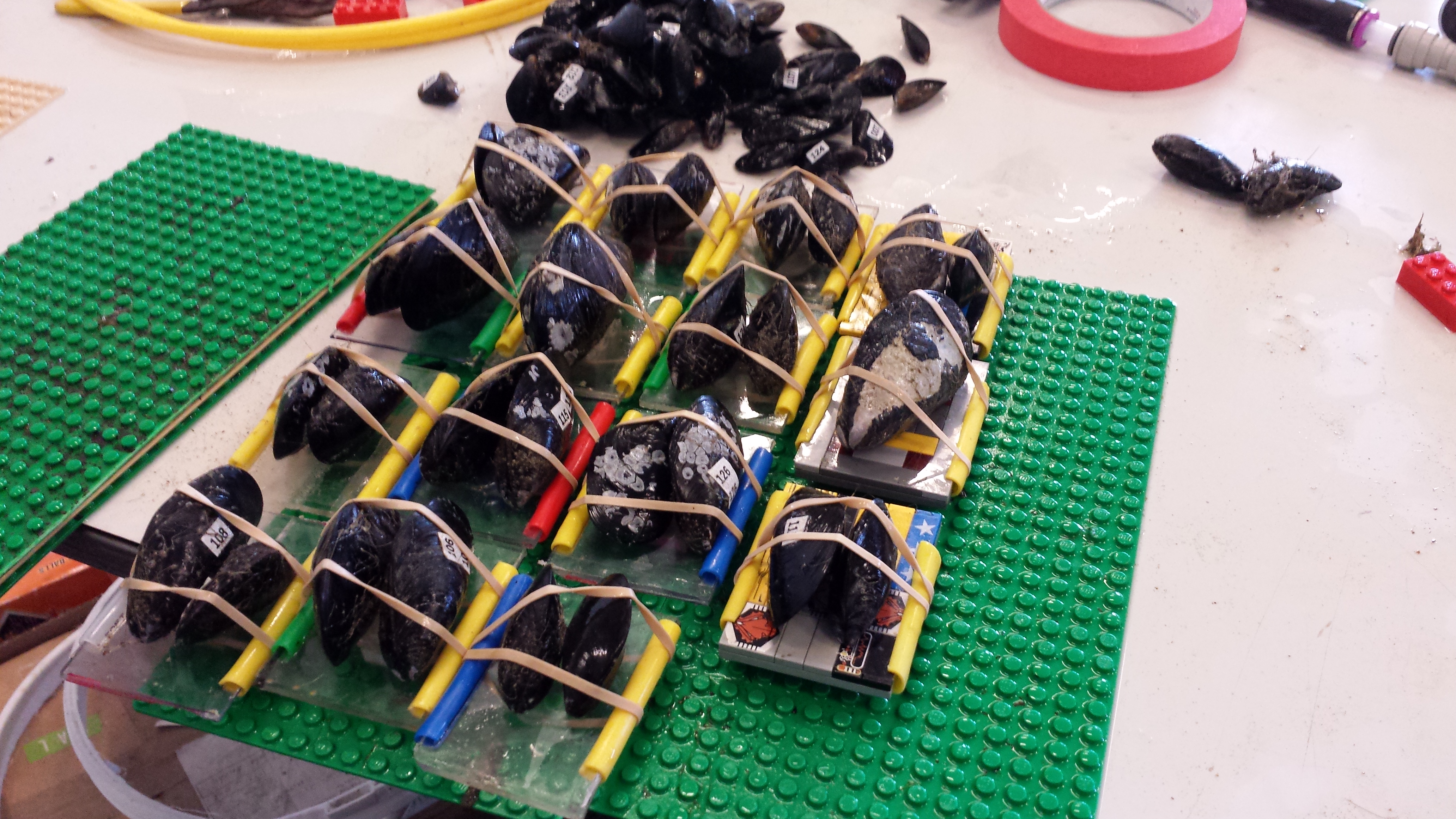

Once I got the mica sheets, I needed a reproducible way to get mussels to attach to them. I came up with a modular design using Legos and pieces of acrylic due to size from a larger sheet. You can purchase loose Legos in various sizes. I found that the 2x3 size worked, but the 2x4 size worked best. Here is the workflow for platform construction:

- Acrylic sheet was cut to size (same size as mica sheets)

- Lego bricks were superglued to the acrylic blocks

- Mica sheets were placed on acrylic blocks and affixed using cut pieces of 1/4” OD tubing, sliced along their length with a razor blade. Tubing slid onto acrylic blocks, pinching the mica sheet in place. See pictures below.

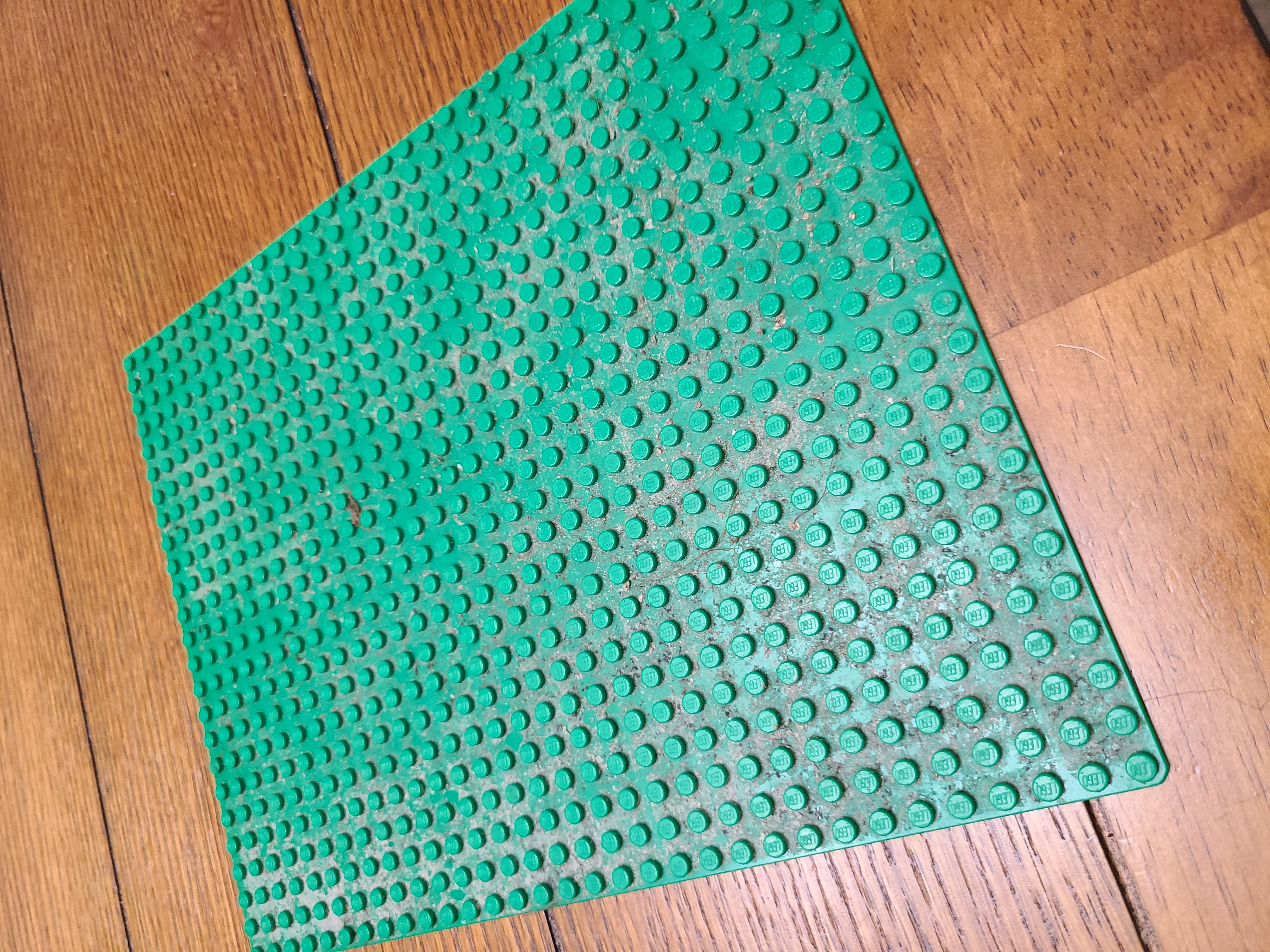

- Blocks were placed in a array on a Lego baseplate. The baseplate may need to weighted so they don’t float - I did this by rubber-banding them to some tiles we had laying around.

- Two mussels were then placed on each platform, valve opening down. To prevent movement, a rubber band was wrapped around each platform, securing both mussels together and to the platform.

| construction steps –> | ||

|---|---|---|

|

|

|

|

|

|

| completed | |

|---|---|

|

|

2.3. Collecting threads

Mussels were labeled using numbered wire-tags, affixed to the shell valve using Loctite super glue - ultra gel control. After adding mussels to platforms, they were exposed to various environmental conditions over three days. The number of threads that each mussel made was recorded (and compared with how many they made beforehand). Threads were then cut at the shell interface. Sometimes multiple mussels attached to the same mica sheet; when this was the case, mica sheets were cut and labeled with the mussel ID that made them. Mica sheets with threads were stored dry between two sheets of paper towel, pressed between two pieces of cardboard, secured with binder clips. Here are some pictures:

Here are some close ups of the plaques:

|

|

|